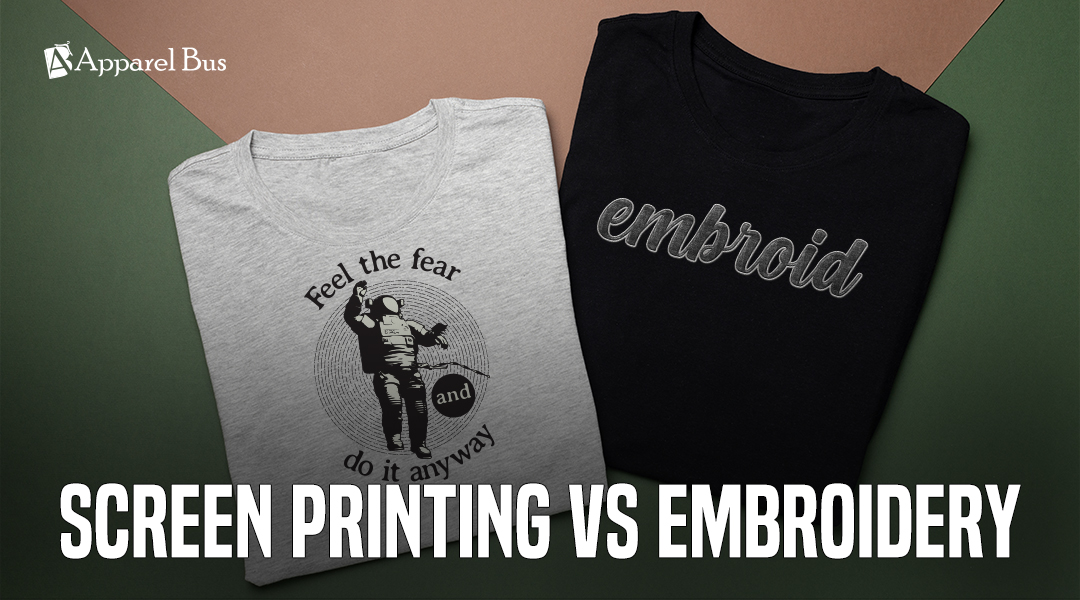

Embroidery vs Screen Printing: Which is the Best for Your Apparel?

Personalized apparel has become the most popular nowadays among individuals, corporates, and large enterprises to highlight their brand identity. From crafting a promotional t-shirt to a sports team uniform, crafting a message that resonates with your audience is priceless. Among the most popular approaches to apparel customization, screen printing and embroidery are the preferred solutions. Understanding the strength of each method is key to maximizing its potential.

In the comprehensive guide, we will explore the differences between screen printing and embroidery, looking into their processes, styling, benefits, and restrictions. This enables you to choose the right kind of method for your needs, whether you're looking to create custom printing and embroidery for corporations or teams or produce simply screen-printing logos to promote conferences and events. Let's get into this embroidery vs. screen printing debate and evaluate the advantages and contrast the offerings.

What is Screen Printing?

Screen Printing, also known as silk screen printing, has become an excellent way of getting any custom design on fabrics. This involves laying out a stencil or mesh screen and pushing ink through into the fabric beneath the screen. The pattern is printed on a piece of fabric as the ink is absorbed into the fibers. It is a widely used method of printing on shirts, hoodies, or any other apparel.

History and Evolution of Screen Printing

Screen printing has its roots as far back as ancient China in 960 AD. The process was refined, however, in the 1900s when the modern methods were introduced. Screen printing is nowadays a popular technique of applying bright, long-lasting designs to fabrics. It is the most preferred method by businesses that require bulk production of custom apparel within a very short duration of time.

Process Overview

-

Preparing the Design: The design is initially reduced and transferred to a stencil or mesh screen. The picture or writing is then transferred onto the screen via a light-sensitive emulsion.

-

Creating the Screen: The screen is a mesh coated with the emulsion and exposed to light to form the negative of the design.

-

Printing Layers of Ink: Ink is applied to the screen, and a squeegee is used to force the ink through the mesh into the fabric.

-

Curing the Ink: Once printing is done, the design is heated to fix or cure the ink so that it does not remove after washing.

What is Embroidery?

Embroidery involves delicate needle and thread work with exquisite stitching. Two techniques are employed to create the design: manual sketching, which offers a personal touch, and machine embroidery, which ensures precision and intricacy. Unlike screen printing, which applies ink on the fabric's surface, embroidery punctures the fabric while adding intricate details.

History and Evolution of Embroidery

Embroidery is one of the oldest methods to decorate textiles; it adorns clothing with intricate embellishments and ornaments. Originally done by hand, embroidery became faster and more accessible after the invention of machine embroidery. Machines can create ornaments and a final touch that adds an exquisite embellishment, and ornaments that beautify the clothing. By using today's technology, we can create high-quality logos, names, artwork, corporate uniforms, branded merchandise, and sports apparel.

Process Overview

-

Preparing the Design: Like screen printing, embroidery begins with the digital design. The design is converted into an embroidery-friendly format.

-

Transferring the Design: The design is transferred to the embroidery machine, which embroiders it onto the fabric with precision.

-

Stitching the Design: The embroidery machine stitches the design onto the fabric, using a thread to create meticulous and intricate patterns on the fabric.

-

Finishing Touches: Once the stitching is complete, excess threads are carefully trimmed, and the finished product undergoes a quality inspection.

Key Differences Between Screen Printing and Embroidery

When deciding between screen printing and embroidery, it's essential to consider factors such as visual appeal, durability, cost, and fabric compatibility. Each method has specific advantages that may make it more suitable depending on the desired outcome.

Visual Appeal

-

Screen Printing: Screen printing is known to create beautiful patterns, flat designs, and meticulous work, which makes it a preferred choice for multi-colored designs and bold graphics. This technique is more specialized for large and attractive prints with exquisite details.

-

Embroidery: Embroidery is one of the oldest ways to add depth and dimension to the design. It is known to create intricate patterns and more polished and sophisticated work, ideal for embroidered logos, premium branding, or high-end merchandise.

Durability

-

Screen Printing: The durability of screen printing usually depends on the kind of ink and type of fabric used. With the passage of time, ink may fade, crack, or peel, specifically if the design is crafted with intricate details and not applied correctly.

-

Embroidery: Embroidery tends to last much longer compared to screen printing. Due to the stitching process, embroidered designs exhibit remarkable durability, resisting fading and cracking even after repeated washing.

Cost

-

Screen Printing: One of the best benefits of screen printing is cost-effectiveness for bulk orders. Once set up, the reduced cost makes it an economical and efficient option for producing apparel such as t-shirts, hoodies, and other apparel.

-

Embroidery: Embroidery is costly as compared to screen printing, especially when ordered in small quantities. Individual items take time to stitch, and highly intricate designs could make the costs shoot up rather rapidly. It is still cheap, though on smaller orders, particularly when the design is not very complex.

Fabric Compatibility

-

Screen Printing: Screen printing will mostly work with smooth, flat materials like cotton, polyester, or a cotton-polyester mixture. It does not work well on hard, textured fabrics because the ink cannot possibly bind to such fabrics well.

-

Embroidery: is extremely diversified and works well on a wider range of fabrics. This method accommodates thicker materials, such as denim, and is especially well-suited for custom embroidery and printing on items like jackets, caps, and polo shirts.

Design Complexity

-

Screen printing is best for bold, straightforward artwork that uses solid colors and larger shapes. It becomes less effective with fine details, small lettering, or complex gradients. Designs that include these elements often require more time and cost, making the process less efficient for intricate patterns.

-

Embroidery, on the other hand, works well for smaller, detailed designs such as logos, names, or monograms. It can reproduce patterns and shading with thread, though very tiny details may not appear as sharp. While embroidery cannot achieve smooth gradients or photographic effects, it delivers a textured and premium finish that gives logos and text a professional look.

Advantages of Screen Printing

-

Cost-Effective for Bulk Orders: One of the best advantages of screen printing is its cost efficiency when you order it in bulk. The more units you order, the more benefits you gain. This is specifically ideal for businesses that need bulk apparel for a particular event or promotional merchandise.

-

Vibrant, Bold Colors: Screen printing allows you a selection of a wide variety of colors that stand out, especially with large, colorful graphics. It's best for creating attention-grabbing promotional items such as festive or trade show-themed t-shirts.

-

Quick Turnaround: Once the setup is established, Screen-printing can be done very quickly, making it an ideal choice for the corporate looking for custom printing and embroidery services to capture the attention of an audience for an event.

-

Ideal for Large Runs: The more you print, the lower the cost per piece. This makes screen printing an excellent choice.

Advantages of Embroidery

-

Professional, High-Quality Finish: Embroidery offers a more sophisticated and polished look for corporate, team uniforms, and small runs. The beautiful and catchy patterns look more premium and elegant than flat, promoted designs.

-

Durability: Embroidery is more durable than screen printing; there's no debate about it. It doesn't fade or dull with the passage of time; even after frequent washes, it always remains the same. The stitching adds a layer of protection to the design.

-

Perfect for Small Orders: Perfect for small orders, as embroidery doesn't demand the same setup as in the case of screen printing. It's more preferable for small orders and corporations that need apparel in small quantities, such as a boutique shop or a small cottage shop.

-

Versatility: Embroidery is ideal on all kinds of fabrics, such as fleece, denim, and leather. It also works best on the custom hats or jackets where other textures get more emphasis to provide appealing patterns..

Which Method is Best for Your Project?

Choosing between screen printing and embroidery entirely depends on your needs and preferences. Here's a quick breakdown of when you need what the most:

Screen Printing

-

Best for: bulk quantities, bold patterns, and vibrant colors.

-

Ideal for: Customized and promotional t-shirts, event merchandise, and plain t-shirt patterns.

-

Best suited for: Corporations and large enterprises that demand bulk apparel with uniform design.

Embroidery

-

Best for: Custom logos, small to medium orders, personal branding.

-

Ideal for: Corporate giveaways, embroidered logos on jackets, and sports team apparel.

-

Best suited for: Embroidered logos, names, and smaller designs on custom hats, jackets, and polos.

Conclusion:

The choice to use screen printing vs embroidery solely lies in project requirements. Screen printing is best suited to large quantities that are in bold colors, whereas embroidery is best suited to more premium-quality, durable custom apparel. The right option will eventually rest on the complexity of design and quantity, fabric, and desired finish.

To begin your custom apparel project, visit our Customization Page to learn about both screen printing and embroidery services. No matter what you are printing, be it a big event or just a small batch of high-end embroidery designs, we have solutions to suit your requirements.

Leave us a comment